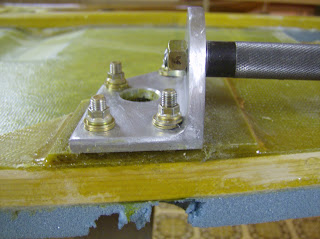

Also I have been getting quite a few tips online on the landing gear attach area. Its time to sit down and scan the newsletters more closely to make sure there isn't anything else I might have missed.

Documenting my progress in constructing a two place canard pusher aircraft.

Last weekend my brother again headed down from Seattle and gave me a hand glassing up the two sides. Each side took a few hours each to prepare and glass up. For the most part everything went togather as planned. However somehow a couple of foam peices shifted while the micro was setting up and I had to cut and reglue that bond.

Last weekend my brother again headed down from Seattle and gave me a hand glassing up the two sides. Each side took a few hours each to prepare and glass up. For the most part everything went togather as planned. However somehow a couple of foam peices shifted while the micro was setting up and I had to cut and reglue that bond.